Processing Capacity:

Feeding Size:

Applied material:

Application Field:

Send E-mail:shuguang_mill@163.com

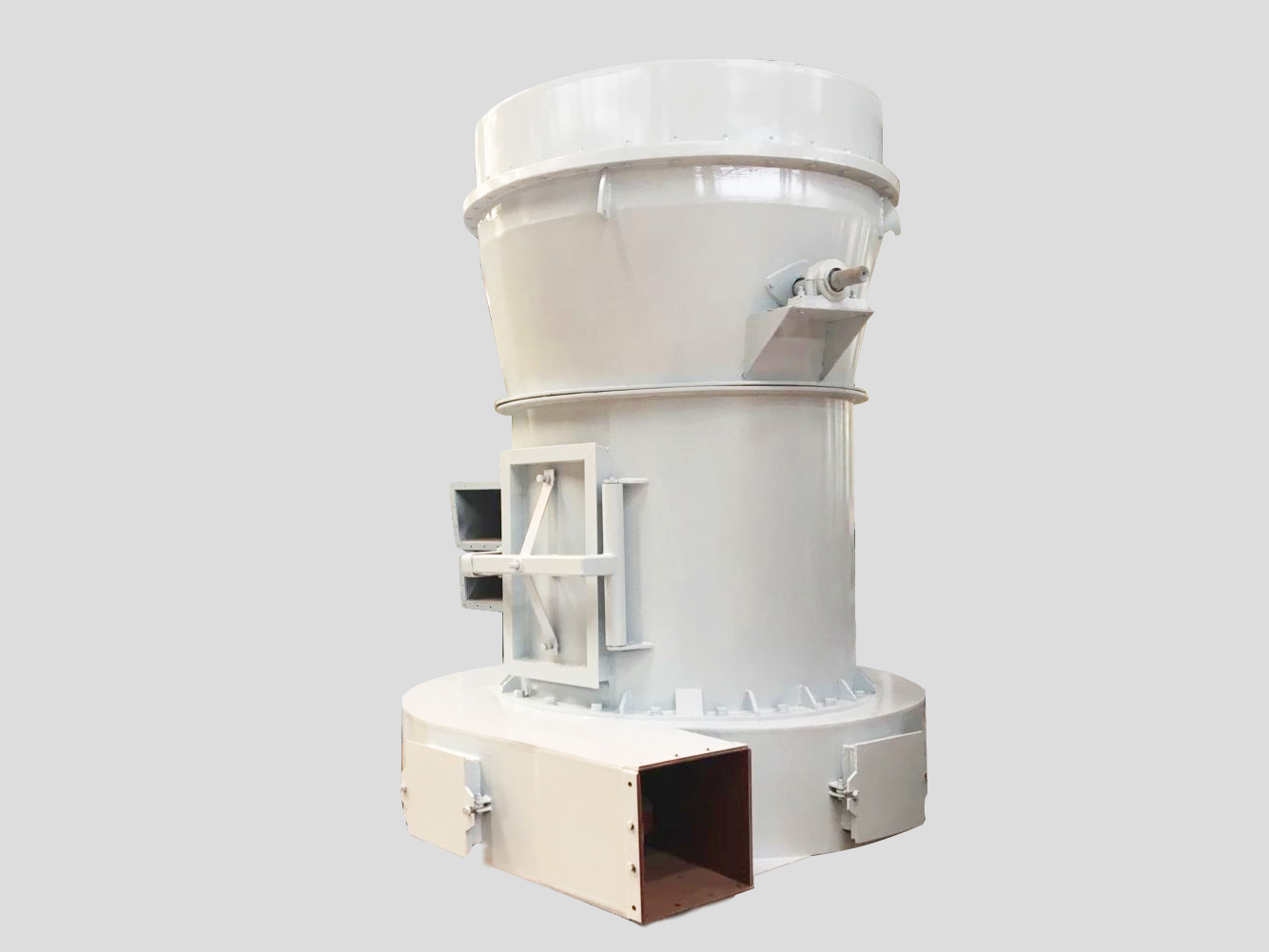

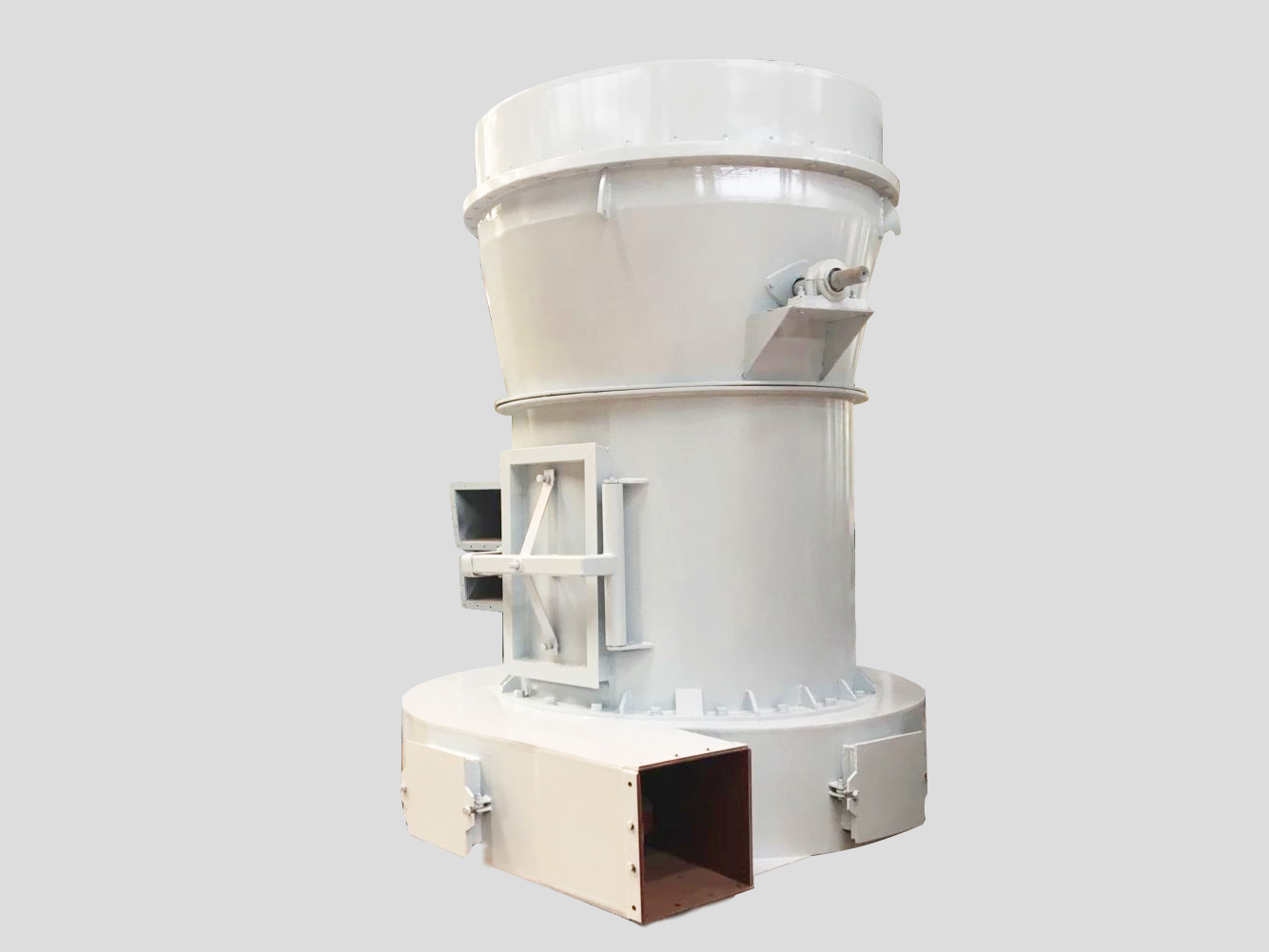

Bentonite Raymond mill can make bentonite fine pulverized processing, thus improve the comprehensive utilization of bentonite.

Structure and Parts

Bentonite Raymond mill structure is mainly composed of motor, spring positioning sleeve, spring rod, grinding roller shaft, grinding ring, grinding roller, blade, spindle, shaft and other components.

Working principle

Bentonite Raymond mill is pressed on the grinding ring tightly under the action of centrifugal force. The material is shoveled from the scraper to the middle of the grinding roller and grinding ring. The material is broken into powder under the action of the roller pressure, then the powder material is blown through the analysis machine under the action of the fan. The qualified material is passed through the analysis machine. The grinder should be returned to the grinding machine for re grinding. Finally, the powder after the grinding is entered into the cyclone separator for the effective separation and collection of the different bentonite.

Advantages

1.the user can control the equipment centrally, not only reducing the demand for the workers, but also effectively reducing the harm to the body of the workers in the production.

2. For the important parts of the equipment, high manganese steel is chosen as the material to make the equipment more wearable and longer life in operation.

3.In the operation, the equipment has a good sealing performance, and the equipment is equipped with silencer and dust removal device, making the production of the equipment more efficient and environmental protection.

4. The vertical structure design reduces the floor area of the equipment and makes the users more time-saving and labor-saving in installation and operation.

5.The equipment is not only excellent in quality and high in grinding efficiency, but also can create higher value for the users, and the market price of the equipment is generally low, which reduces the initial expenditure of the users. As a manufacturer, our newly designed Raymond mill is more practical, the hardness and wear resistance of grinding rolls, grinding rings and shovels are improved, the service life is generally increased by more than two times, the production cost is reduced, the equipment runs smoothly and without abnormal phenomena, the sealing and lubrication performance of special lubricant paste is good, and the oil-saving is increased by 60%. Performance, operation rate is over 95%, output per hour is increased by over 40%, and economic benefit is good.