Processing Capacity:

Feeding Size:

Applied material:

Application Field:

Send E-mail:shuguang_mill@163.com

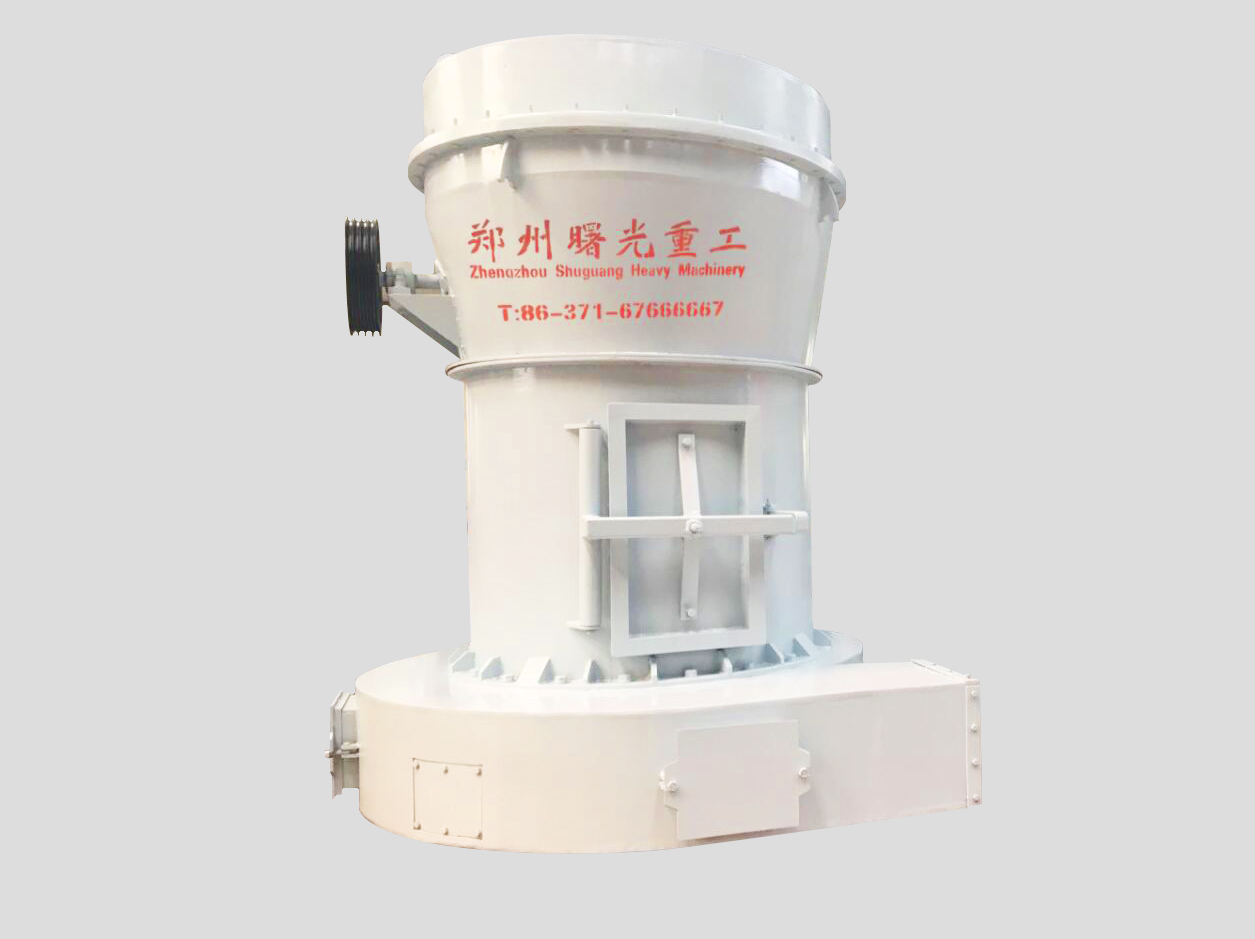

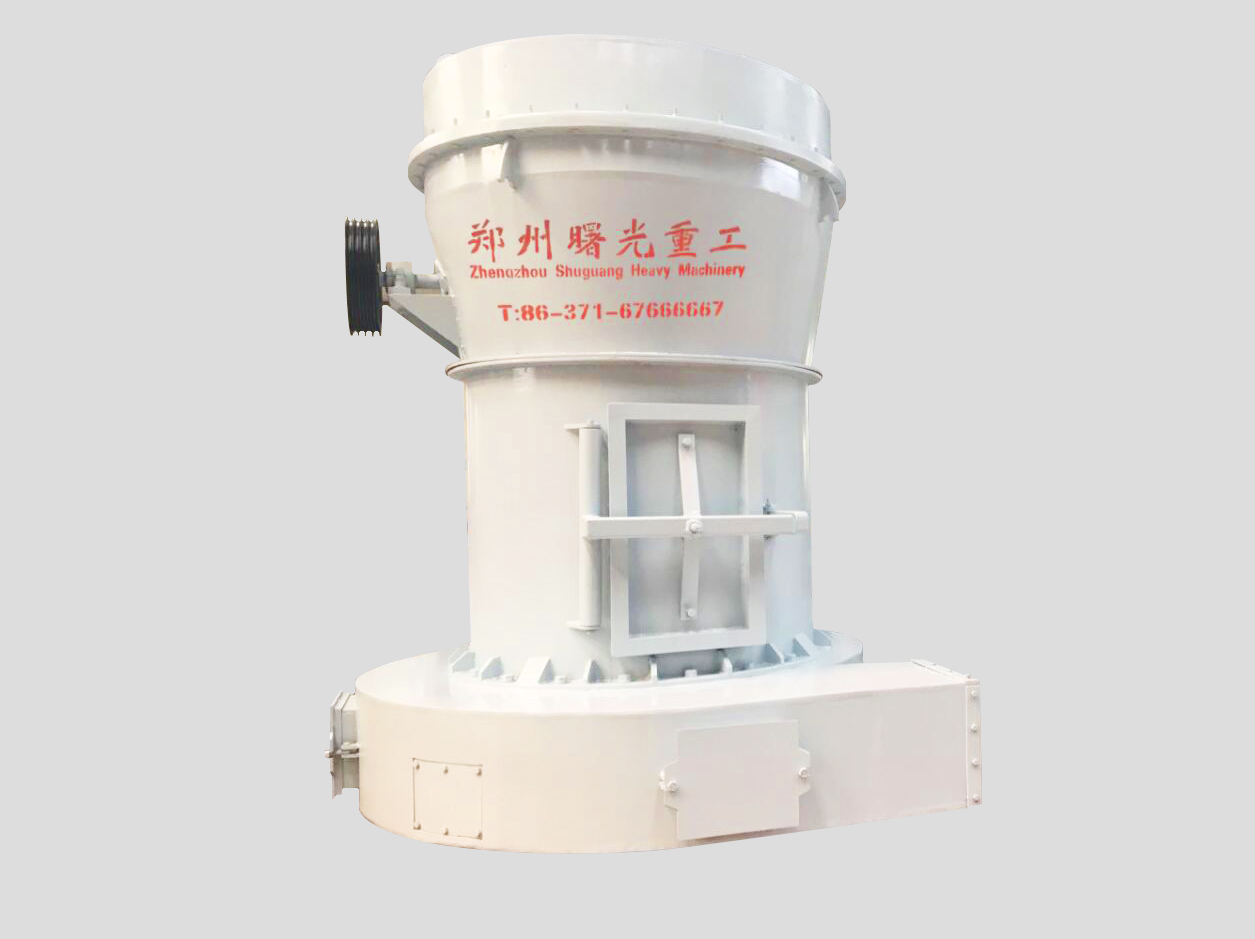

Introduction

Plaster is an important building material and its powder is the raw material for building materials market. Plaster production shows that plaster powder needs to be broken, grinding and forging three processes, of which plaster grinding is an important factor restricting the development of plaster powder industry. In the process of grinding, plaster will break down water and easily be bonded to the surface of the grinding parts or equipment, which causes the failure of production equipment and the difficulty of equipment maintenance, so that the output of the powder is difficult to be improved. To this end, designers and manufacturers have been looking for suitable grinding equipment.

In recent years, the application of Plaster Raymond mill powder machine, designed and developed exclusively by Shuguang manufacturer, shows that it has successfully solved the technical problem in plaster grinding, and made the output increase by more than 20%~50% without increasing the investment of equipment. The machine can basically meet the production needs of medium and small gypsum enterprises.

Working principle

Feed the material from the side entrance of the machine, fall on the high speed rotating disc, get the high centrifugal force by the impact grinding of the roller, and throw it back into the rotating disc and throw it back into the rotating disk, and then it is pulverized, and the parts of the crushed material rotate at high speed at the same time. A suspension column is formed, and the material is smashed in the reciprocating and circumferential cross movement. In addition, some material falls into the gap between the grinding roller and the grinding ring and is crushed by the extrusion. The airflow blows the crushed material into the milling machine, and enters two cyclone separators to get the finished material; the upper exhaust is introduced to the fan for recycling, and the small part of the gas is discharged through the small cyclone collector.

Features

1. Simple structure

The working part is composed of a rotary grinding roller and a grinding roller, with bearings and precision parts inside. The wearing parts are cast with high chromium cast iron and manganese steel, the working parts are wear resistant, the repair workload is very small, and the replacement parts are also very convenient.

2. Install easily

It is composed of main engine, separator, fan, cyclone separator and small cyclone dust collector, each of which has an integral rack, which is easy to install.

3.Small noise

Relative vibration mill and pendulum mill, Plaster Raymond mill has little noise at work, and the machine runs smoothly. And it has been used for more than 2 years and runs normally.

4. less dust

The machine is controlled by the exhaust volume, maintains the micro negative pressure of the feeding port, and the exhaust volume is 2000~3000m /h. Because of the dual cyclone dust collector, the dust content is less, and the single machine bag type dust collector can meet the requirements of environmental protection.

5. The size of the feeding block is large

The bulk of the feed gypsum stone can reach 50~80mm, and the feeding block of the pendulum mill is only 3~5mm. Compared with the pendulum mill, the intermediate link of two stages can be saved.

As a manufacturer, our newly designed Raymond mill is more practical, the hardness and wear resistance of grinding rolls, grinding rings and shovels are improved, the service life is generally increased by more than two times, the production cost is reduced, the equipment runs smoothly and without abnormal phenomena, the sealing and lubrication performance of special lubricant paste is good, and the oil-saving is increased by 60%. Performance, operation rate is over 95%, output per hour is increased by over 40%, and economic benefit is good.