Processing Capacity:

Feeding Size:

Applied material:

Application Field:

Send E-mail:shuguang_mill@163.com

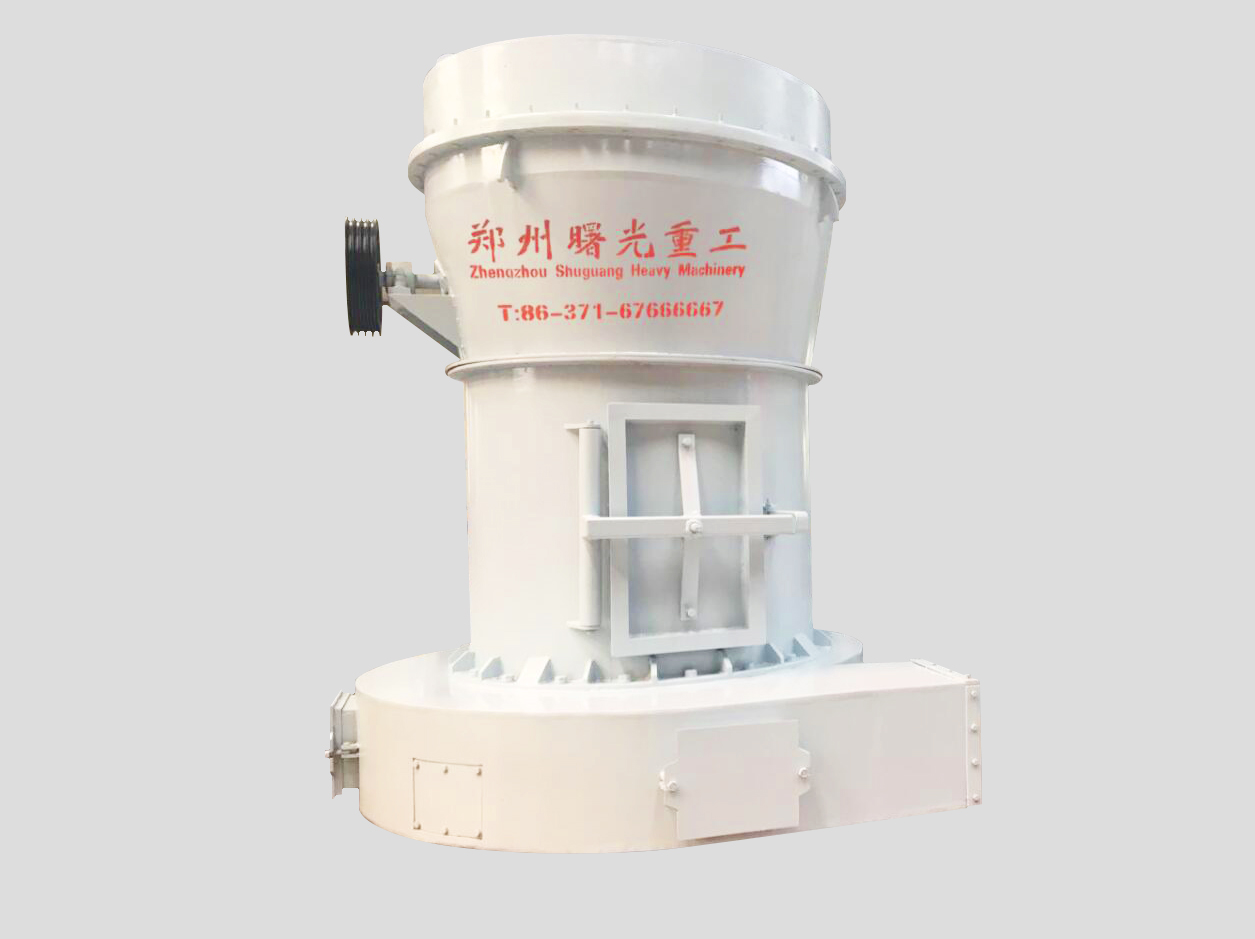

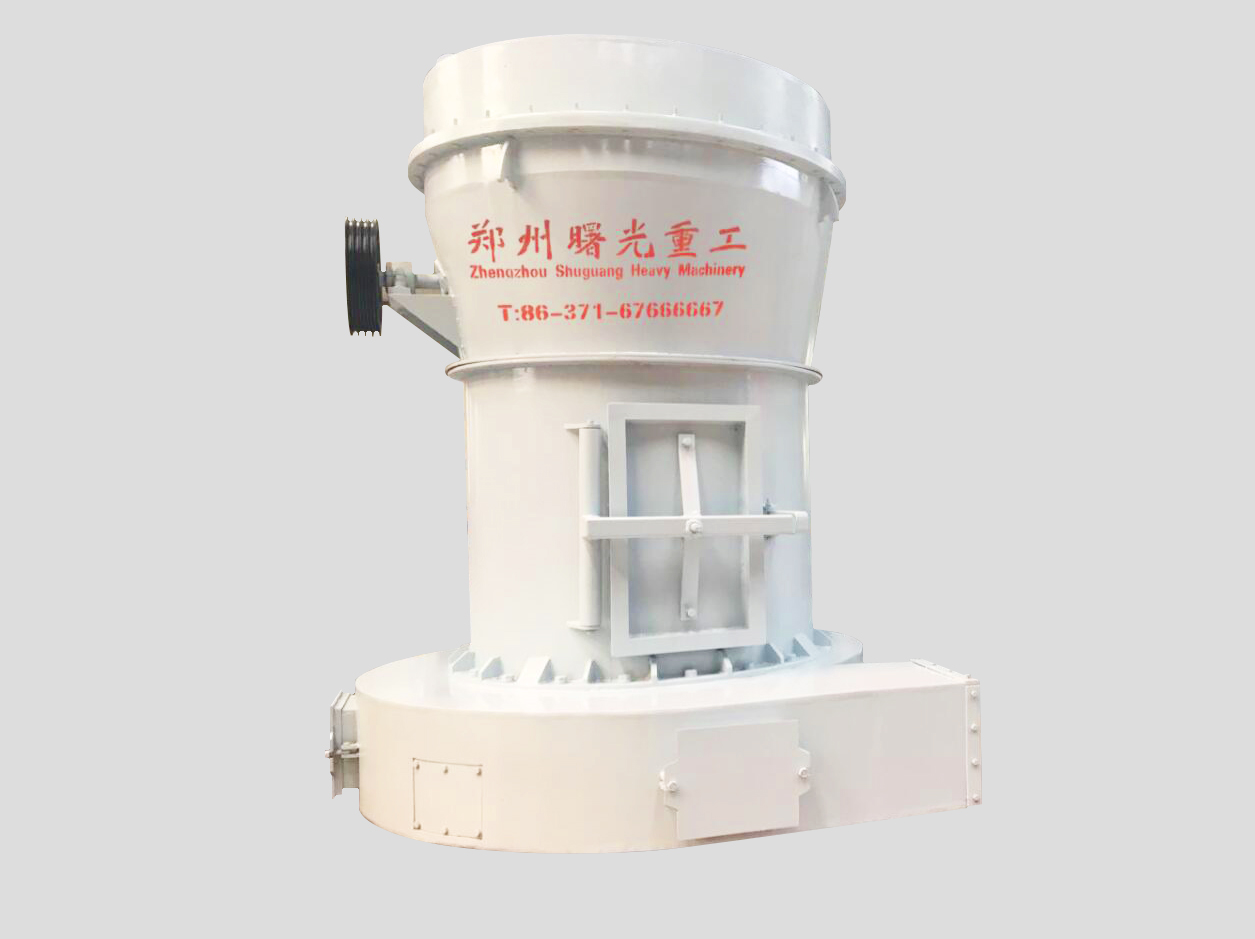

Application of high pressure raymond mill: The machine is widely used in quartz, recrystallization, calcite, potassium feldspar, talc, marble, limestone, dolomite, fluorite, lime, activated clay, activated carbon, bentonite, kaolin, cement, phosphate rock, gypsum, graphite , Manganese ore, titanium ore, copper, chrome ore, refractory materials, insulation materials, carbon black, clay, iron oxide and other Mohs hardness below 9.3, humidity below 6% of non-flammable and explosive minerals, Chemical industry, fertilizer and other industries more than 300 kinds of materials, high-fine powder processing, finished grain size in the range of 30-425 mesh (0.613 mm -0.033 mm), according to the needs of a small part of the highest material fineness of up to 1000 mesh (0.013 mm ). Working process of High pressure mill: High-pressure milling machine host, roller hanging hood on the fastening of the pressure of 1000-1500 kg high-pressure spring. After the work began, the roller rotates around the main shaft, and under the action of high pressure spring and centrifugal force, close to the grinding ring rolling, the pressure is 1.2 times higher than the Raymond Mill under the same power condition, so the production is greatly improved. When the grinding material into the grinding chamber, the shovel shovel into the grinding roller and grinding ring between the rolling, rolling powder with the blower of the circulating wind into the analysis machine, qualified powder with the air into the cyclone powder Equipment that is finished, large particles back to the material grinding. Recycling the wind back to the blower and then repeat the above process, the wind is into the bag filter purification. When the grinding roller and grinding ring wear to a certain extent, adjust the length of high-pressure spring, roller and ring to maintain a constant between the rolling pressure. Thus ensuring stable production. Parameter of high pressure mill

| Model Parameter | High pressure 96 | High pressure95 | High pressure 93 | High pressure 86 | High pressure83 |

| Feeding size(mm) | ≤25 | ≤15 | ≤25 | ≤20 | ≤20 |

| Output size(mm) | 0.125-0.044 | 0.125-0.044 | 0.613-0.013 | 0.125-0.044 | 0.125-0.044 |

| Capacity | 4-55 | 3-38 | 3.5-40 | 3-33 | 3-37 |

| Speed(r/min) | 130 | 130 | 160 | 160 | 160 |

| Ring Dia (mm) | 970 | 950 | 910mm | 860 | 830 |

| Roller Dia (mm) | 320 | 310 | 300mm | 300 | 270 |

| Height (mm) | 160 | 170 | 160mm | 150 | 150 |

| Motor (KW) | y225m-4-37 | y225s-4-37 | y225m-8-30 | y225m-8-22 | y225m-8-22 |

| Fan (KW) | y200L-4-37 | y200L-4-30 | y180m-2-22 | y160E-4-18.5 | y160E-4-15 |

| Analysis machine (KW) | yc120-4A-5.5 | yc122-4A-5.5 | y112m-6-3 | y112m-6-2.2 | y112m-6-2.2 |

Shuguang company has been guided by the "quality of survival in good faith and development" concept of development, won the majority of customers praise,shuguang company will be more depending on the quality of life, the user for God. The user is everything for us. We will always follow the responsibility for each process, responsible for each product, for each user is responsible for the quality and dedication to serve you.Warmly welcome you at any time to visit our company ordered! Tel: 13523465141 Contact: Mr.Zhao QQ:1612683601 E-mail:shuguangzhongji@163.com Website: www.leimengmo168.com Address:No.19,longjiang west road,zhengzhou