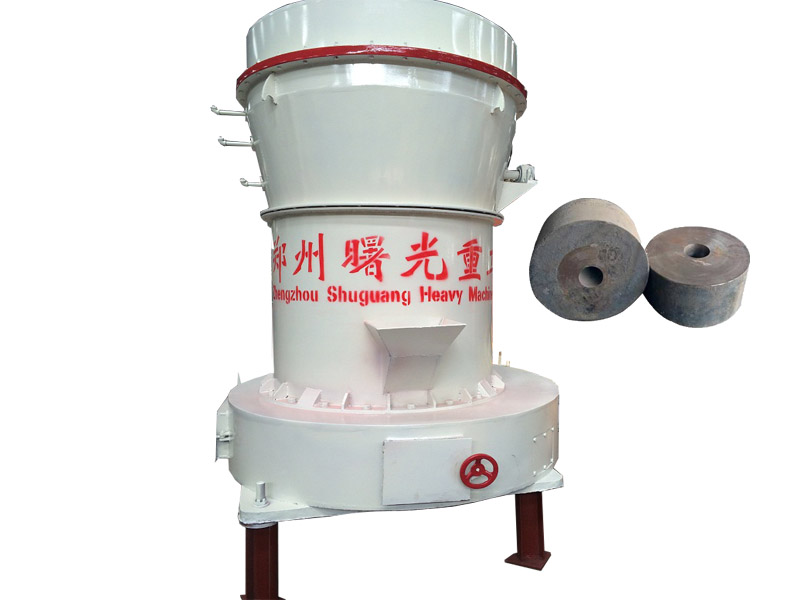

Kaolin Raymond mill kaolin roller mill for sale

Kaolin Raymond mill kaolin roller mill for sale

Processing Capacity:

Feeding Size:

Applied material:

Application Field:

Send E-mail:shuguang_mill@163.com

Zhengzhou shuguang heavy machinery co., LTD. Has absorbed the world's advanced grinding technology. According to the principle of fluid mechanics, it is designed to perform better than similar products. The emergence of this kind of Raymond mill, solve the problem of the world in fine flour processing, in the domestic and foreign ground mill market is highly praised.

Characteristics of Raymond mill in kaolin:

1. The kaolin Redmond mill is a three-dimensional structure, which occupies a small area and is a complete set of sex. It is expected that the finished product of the finished product will become a production system independently.

2. The fine degree of fine powder of finished product is uniform, and the pass sieve rate is 99%, which is difficult for other mill equipment.

3. The transmission device adopts sealed gearbox and belt wheel, which is stable and reliable.

4. The important parts are all made of high quality steel. The wear-resistant parts are made of high performance wear-resistant materials. The machine has high wear resistance and reliable operation.

5. Centralized control of electrical system, easy to use.

The composition of Raymond mill structure in kaolin:

Kaolin Raymond mill is mainly composed of main engine, analyzer, fan, product cyclone separator, micro-powder cyclone separator and duct. Among them, the main engine consists of frame, air inlet and volute, blade, grinding, ring and shell.

The working process of Raymond mill in kaolin:

Machined materials into kaolin Raymond mill host after grinding room, due to the main shaft, the effect of rotating centrifugal force when roller swing outward, press in grinding ring, shovel knife scooping up material sent to the between grinding roller and grinding ring, along with the roller rolling grinding, milling and to achieve. After grinding material, powder with blower wind circulation through the analysis of machine for sorting, fine fall back into the grinding chamber through the coarse material resharpening, qualified fine powder increases with airflow into the cyclone powder, the powder tube drainage is the finished product. The air flow passes through the cyclone collector and enters the blower to form a closed-loop cycle, so that the machine can work continuously. After the residual air pipe enters the dust collector through the purifying back out of the machine.

Purchase kaolin Raymond mill, please identify professional Raymond mill manufacturer! Click to get Raymond mill price information!

Kaolin Raymond mill parameter:

|

Type |

HGM-80 |

HGM-100 |

|

AverageDiameter |

800 |

1000 |

|

Mainenginefeedingsize |

Ringroller |

21 |

27 |

|

Rollerring |

3 |

3 |

|

Mainenginefeedingsize |

≦10 |

≦10 |

|

finshedproductsize |

Micron |

5-45 |

5-45 |

|

Meshsize |

3250-325 |

3250-325 |

|

Yield |

600-4000 |

900-6000 |

|

Motorpower(KW) |

mainengine |

5-25 |

5-45 |

|

powerselectingmachine |

18.5 |

37 |

|

fanmachine |

45 |

75 |

|

feeder |

0.06 |

0.06 |

|

Unloadingvalve |

0.75 |

0.75 |

|

Dimension(m) |

13.9×4×6.2

|

18×4.6×8.6

|

Send Inquiry

We guarantee that your information will not be divulged to third parties and reply to you within 24 hours.

Please enter your demand such as Raw material type, Capacity, Feeding material size, Final product size, etc. To become our quality clients will have access to a discount of contract!