Processing Capacity:

Feeding Size:

Applied material:

Application Field:

Send E-mail:shuguang_mill@163.com

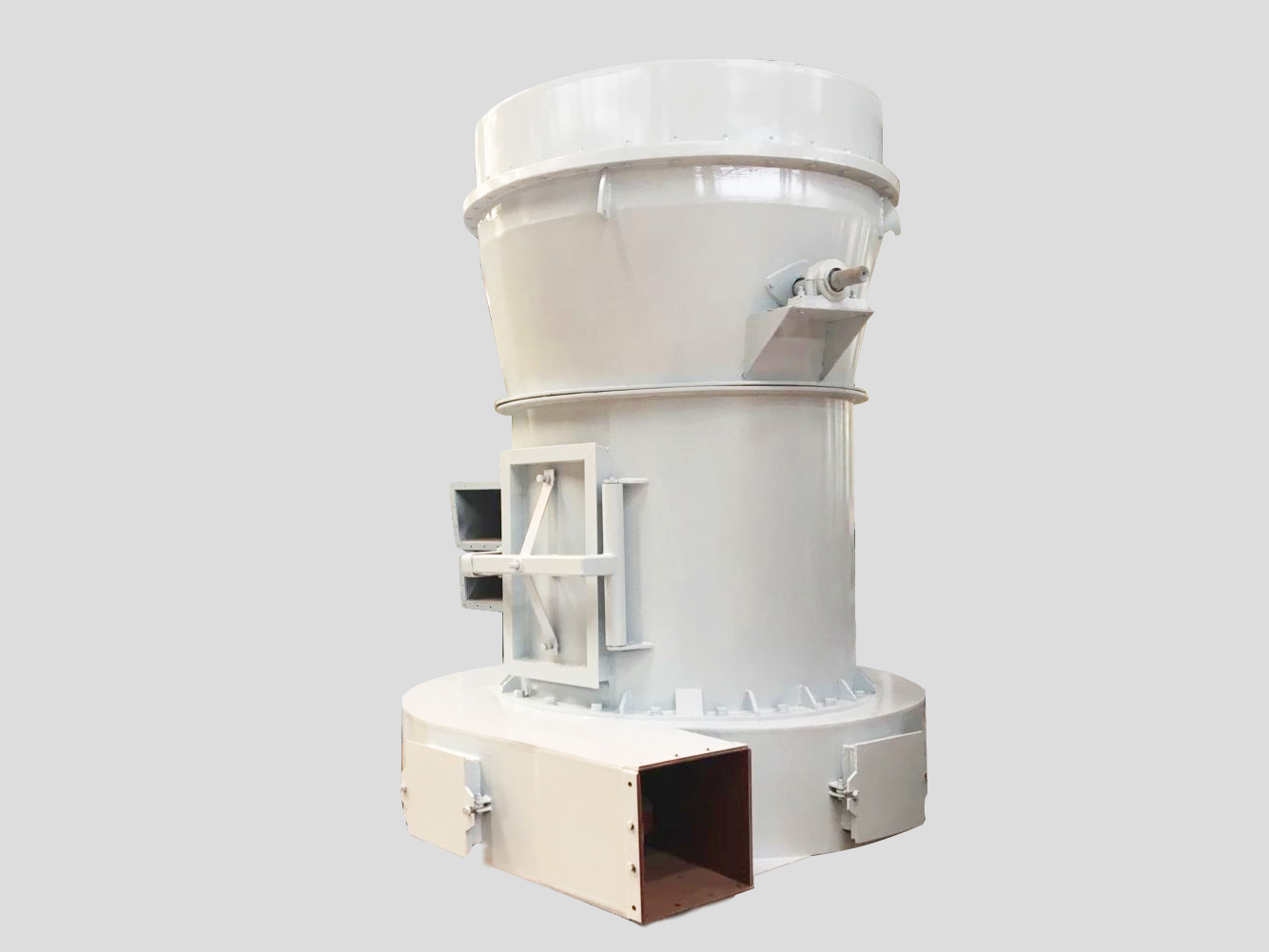

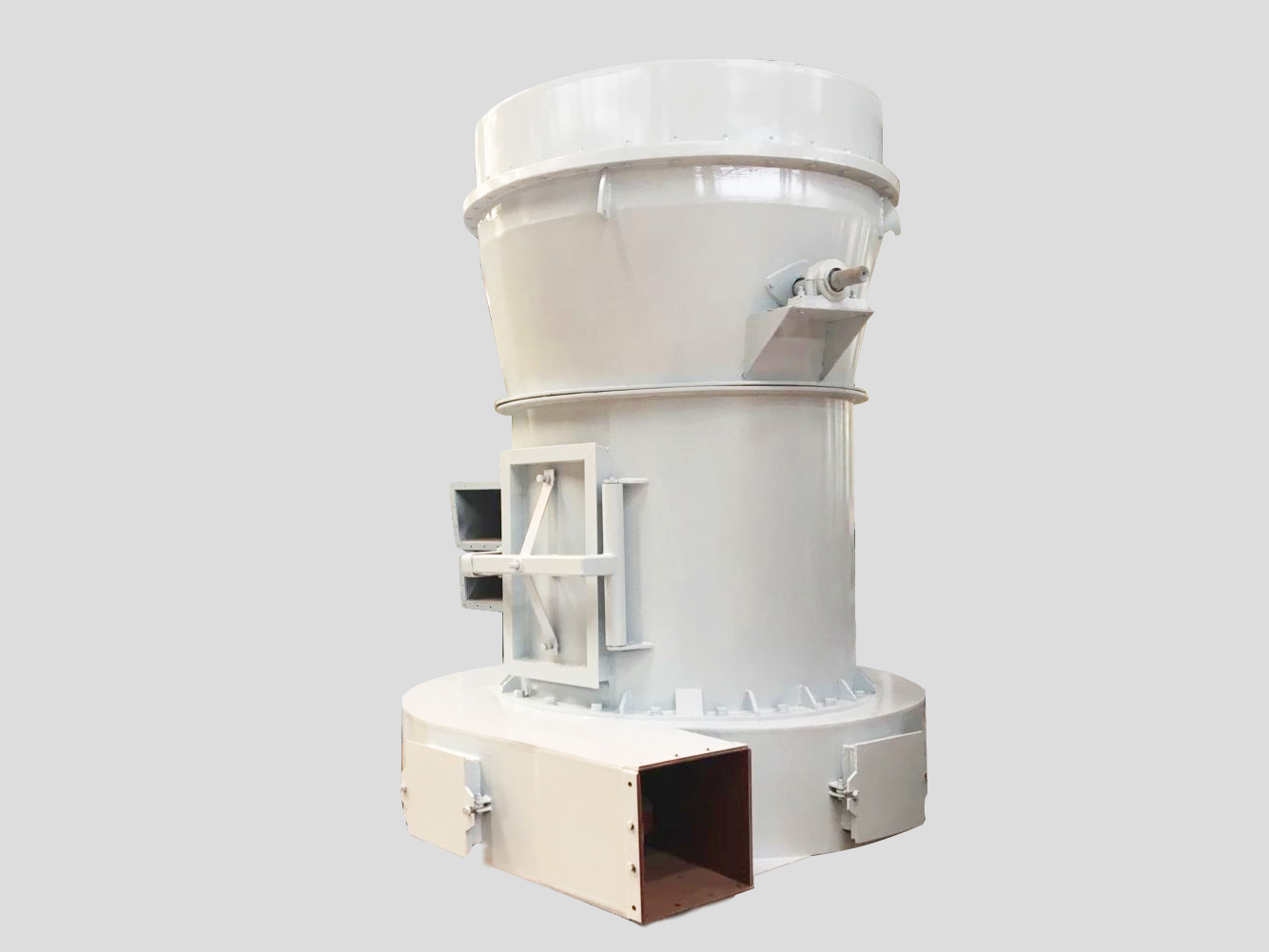

Introduction to barite Raymond mill Barite Raymond mill is also called Raymond mill, is a kind of mineral powder grinding equipment, can be used for grinding mok's hardness of magnitude 9.3 or less rock, such as calcite, potassium feldspar, talc, marble, limestone, dolomite, glass, insulation materials, etc., especially for barite materials, the finished product 80-325 mesh size range adjusted, and part of the material can be as high as 2000 mesh. Barite is a more common mineral of barium, and its composition is barium sulfate. It is produced in low temperature hydrothermal vein. The crystal of the barite is a large tube, and the crystals are gathered together to form the shape of a rose or a forked crystal, which is called a crown - like barite. Barite can be used as a white pigment. In addition, the material has been dealt with by the equipment, such as the barite Raymond mill. Can be used in chemical industry, paper making, textile packing and other industries. Barite Raymond mill advantage 1. Small footprint: the barite Raymond mill adopts the three-dimensional structure, which is small compared to other similar equipment. 2. Large scope: it can be used for the grinding of various materials with the hardness below 7. Durable: the main components of the barite ramon mill are made of high quality material, and the process is fine, which ensures the high efficiency and good wear resistance of the equipment. 4. Simple operation: less production and less than 25mm of materials can be processed directly into the machine. The working principle of barite Raymond mill The material shall be sent to the main grinding chamber of the barite Raymond mill continuously. Due to the centrifugal force of the rotation, the grinding roller swings outward, pressing the material to the grinding ring and the grinding of the material to the grinding roller, and the grinding material is met by the rolling of the grinding roller. The pulverized powder is carried away by fan air. According to the analysis machine, the fine powder can be separated from the air flow through the pipe into the large cyclone collector, and then the powder can be discharged as the finished product. In barite Raymond slow indoor by grinding material has certain moisture content, the grinding heat production, moisture evaporation, and the pipeline interface is not tight, air is sucked into the outside world, make the circulation pressure increased, in order to ensure the barite Raymond slow machine work under negative pressure condition, the increase of gas flow through ductwork into dust catcher, purified the back into the atmosphere.

| Type | HGM-80 | HGM-100 | |

| AverageDiameter | 800 | 1000 | |

| Mainenginefeedingsize | Ringroller | 21 | 27 |

| Rollerring | 3 | 3 | |

| Mainenginefeedingsize | ≦10 | ≦10 | |

| finshedproductsize | Micron | 5-45 | 5-45 |

| Meshsize | 3250-325 | 3250-325 | |

| Yield | 600-4000 | 900-6000 | |

| Motorpower(KW) | mainengine | 5-25 | 5-45 |

| powerselectingmachine | 18.5 | 37 | |

| fanmachine | 45 | 75 | |

| feeder | 0.06 | 0.06 | |

| Unloadingvalve | 0.75 | 0.75 | |

| Dimension(m) | 13.9×4×6.2 | 18×4.6×8.6 | |