Processing Capacity:

Feeding Size:

Applied material:

Application Field:

Send E-mail:shuguang_mill@163.com

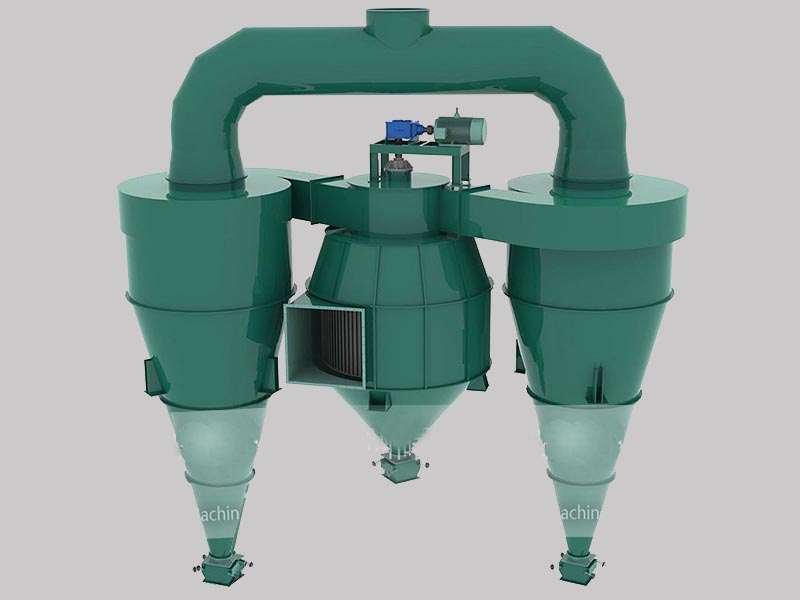

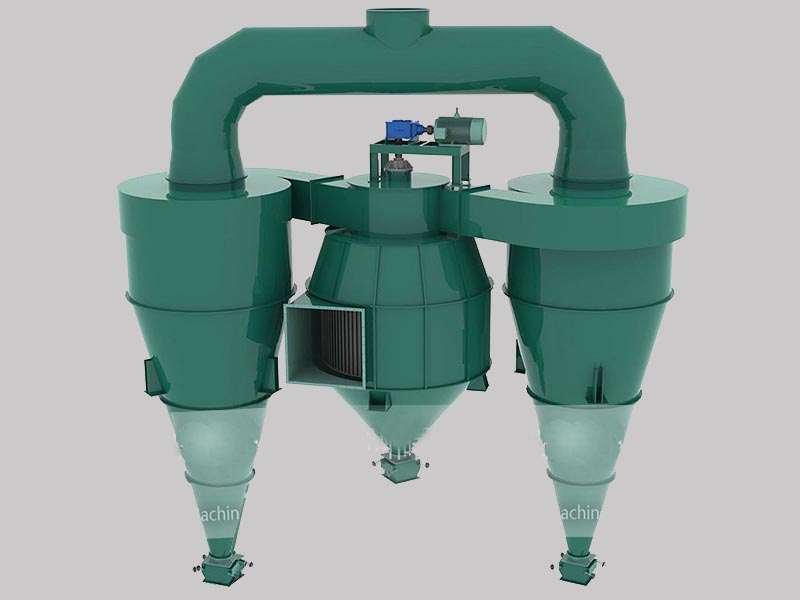

1. advanced separation principle: break through the traditional washing sand separation process principle, using the V type separator and the planar eddy current cage separator compound, greatly improve the system capacity, both because of the v-shaped separator as static separator, no moving parts, made of steel plate for large undisturbed sand on a grading, greater than a certain size of particles directly into the finished product conveying belt away. Fine powder of undisturbed sand, along with the air into the secondary separation of the separator and is less than 0.075 mm particles into the rotor by the cyclone collection, after the part is greater than 0.075 mm particles of delay between the guide vane and the cage rotor clearance falling into the coarse powder cone collect another part of the greater than 0.075 mm particles into the dynamic sorting machine, because of the cross section increases, the wind speed is reduced, in under the action of gravity into the coarse powder collecting cones. According to user's requirement, different modulus of sand can be configured.

2. Higher classification accuracy

In the sorting machine, the "vortex rectifier" is adopted to obtain the national patent, and the air flow in the rectifier is not rotated in relation to the rotor, and the driving power and system wear are significantly reduced. The material is cleaned repeatedly in the constituency, the classification accuracy is higher and more accurate.

3. Easy to operate

The classifier adopts inverter stepless speed regulation, and the quality adjustment is convenient, sensitive and reliable.

4. High grade efficiency

According to the physical and chemical properties of gravel, increase the area of the grading area, so that the material can be dispersed thoroughly to ensure the classification efficiency.

5. Maintenance of wear-resistant design.

The main parts of the separator are: disperser, fine material collector, side wind adjustment board, main wind adjustment plate, multi-channel separator and other main parts. Using imported wear-resisting steel plate and wear-resisting ceramic and boiler steel, the service life is improved effectively. The whole machine has been adjusted for dynamic balance, running smoothly in full speed range.

6. The system adopts double interlock air valve and inner circulation wind to effectively reduce the air leakage and reduce the pollution of dust emission in operation.

In working status, through the drive belt drive shaft rotation speed regulating motor, sand and gravel through the separation chamber bottom static V selected device after processing into the separation of indoor, and then collected through setting in the coarse sand cone of up and down the passage between the two cone falls on the distributor, distributor with vertical shaft turn, the application of the inertial centrifugal force, under the action of round evenly dispersed, decentralized stone in the circulation fan into the separation chamber of high speed air flow, the heavy particles of stone by the effect of inertial centrifugal force is flung to the sorting of interior wall. Collision after losing steam along the wall slid down and landed on coarse sand cone in the collection, the rest of the sand particles are rotating rolls up rising air through the effect of rotating wind leaf, part of the coarse sand particles were thrown into the separation chamber inside wall, losing steam along the wall down after a crash, fall in the coarse sand collector.

After the coarse sand and fine sand are passed through the strong wind blades, the rising air flow continues to rise through the vertical guide blade into the secondary division. Formation sand flow in rotating cage rotor of a strong and stable plane under the action of eddy current, make the coarse sand under the action of centrifugal force was thrown to the vertical guide vane after losing momentum, fall in the coarse sand cone in the collection, through the coarse sand in the tube into the shipping department. The disqualified fine gravel enters its interior through the cage rotor and enters the high efficiency and low resistance cyclone dust collector with the circulation wind and then slips into the fine sand collection cone.