Processing Capacity:

Feeding Size:

Applied material:

Application Field:

Send E-mail:shuguang_mill@163.com

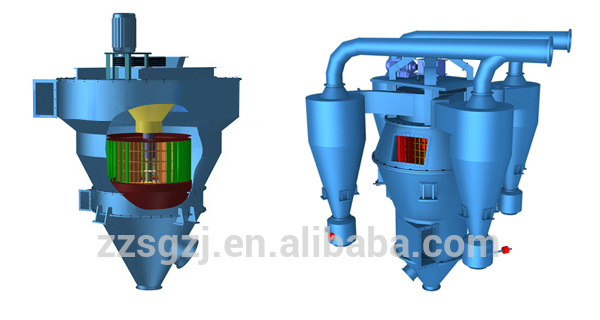

High performance slag ultrafine powder selecting machine

Brief Introduction

1.Shuguang Sepax high performance vortex powder selecting machine is on the basis of the experience which from the international most advanced powder selecting principle,using aerodynamics analysis method and it is the latest technology product.

2.The machine break the conventional closed-circuit grinding system ” coarse,fine powder ” two separation theory ,make the material “ one divided into three ” ,namely the coarse powder,middle coarse powder and fine powder;

3.This system has simple configuration,low cost,can greatly increase the mill output.

4.Its internal structure is reasonable ,the powder selecting effect is obvious,it is the first choice which after execution of new cement standard to improve product quality of grinding syetem,lead the new trend of powder selecting machine technology innovation. slag ultrafine powder selecting machine

Technical Parameters

| Type | Fineness R0.08(%) | Air volume (CBM/h) |

Speed (rpm) |

Power (KW) |

Maximum output (t/h) |

Production (t/h) |

| S-250 | 0-3 | 15000 | 250-500 | 11 | 50 | 10-18 |

| S-350 | 0-3 | 21000 | 220-450 | 18.5 | 90 | 15-28 |

| S-500 | 0-3 | 30000 | 180-400 | 22 | 120 | 20-40 |

| S-750 | 0-3 | 45000 | 160-340 | 30 | 150 | 30-50 |

| S-1000 | 0-3 | 60000 | 130-300 | 37 | 210 | 40-70 |

| S-1250 | 0-3 | 75000 | 130-280 | 37 | 250 | 50-85 |

| S-1500 | 0-3 | 90000 | 130-260 | 45 | 300 | 75-100 |

| S-1750 | 0-3 | 105000 | 120-250 | 55 | 360 | 85-120 |

| S-2000 | 0-3 | 120000 | 120-240 | 55 | 420 | 110-140 |

| S-2500 | 0-3 | 150000 | 110-200 | 75-90 | 520 | 130-170 |

| S-3000 | 0-3 | 180000 | 110-180 | 90-110 | 600 | 150-200 |

| S-3500 | 0-3 | 210000 | 110-180 | 110-132 | 690 | 180-230 |

| S-4000 | 0-3 | 240000 | 110-180 | 132-160 | 780 | 200-260 |

Working principle

1.In working condition,high speed motor drives the vertical transmission shaft to rotate through the transmission device;

2.The material access the chamber of separator by the feeding port which on the top of separator, then falls on the scattering plate by two pyramidal which set in the coarse powder collecting cone and powder pipe;

3.The spreading plate rotate as the vertical transmission shaft,the material scattered around evenly by the inertial centrifugal force;

4.The scattered material under the action of high speed airflow which through the outer fan by inlet port into the chamber of separator,the materials which is coarse particles was thrown to the inner wall surface of the powder selecting chamber by inertial centrifugal force;

5.Then it lose kinetic energy and slide down along the wall after the collision,into coarse powder cone,the rest of the particles are rolled up by rotating airflow,through the role of wind area,clash by the big wind leaf, another number of coarse particles were thrown to the wall surface of the powder selecting chamber,lose kinetic energy along the wall slip after the collision,fall into coarse powder collecting cone.

6.After the middle coarse powder and fine powder through the wind leaf,with the action of upflow,continue to rise into the two stage separator area through the vertical guide blade .

7.Planar eddy current effect of dusty airflow is formed in the cage rotor rotation of the strong and stable,the coarse powder which under the action of centrifugal force throws to vertical guide vane after loss kinetic energy,fall into middle coarse powder collecting cone,discharge through the coarse powder tube.

8.The fine powder which satisfied demand will enter inside through the cage rotor,with circulating air enters the high efficiency and low resistance cyclone separator, then slipped into fine powder collecting cone into a finished product. slag ultrafine powder selecting machine

Pictures for reference

About Us

Zhengzhou Shuguang Heavy Machinery Co.,Ltd

1.Zhengzhou Shuguang Heavy Machinery,founded in 1993,is an integral system that produce R&D,production and sales.

2.We are located in 19th,Longjiang west road,Shangjie district,Zhengzhou city,Henan,China.

3.Our Company produce Raymond mill,Superfine Grinding mill,Three ring micro powder mill,Rotary dryer,Ball mill,Jaw crusher,Impact crusher,Hammer crusher,Cone crusher,Coal gasifier,Vibrating Scree,Vibrating Feeder,stone and sand production line etc.

4.Our products are well known to the international market such as America,Italy,Chile,Sri Lanka,Australia And so on.

5.We warmly welcome and expect strong support from more customers,We believe that science and technology create brand and integrity creates glory.We will serve and repay our society as always be more excellent products.

Contact Us

If you are looking for this machine,please contact us now!

we would like to send you more details and best price,in order to save your time,at the same time,please tell us your requirement:

such as material type,capacity,material size,fineness and so on,thanks!